For many years, it’s been identified that delicate chemical patterns exist in steel alloys, however researchers thought they had been too minor to matter — or that they bought erased throughout manufacturing. Nonetheless, latest research have proven that in laboratory settings, these patterns can change a steel’s properties, together with its mechanical power, sturdiness, warmth capability, radiation tolerance, and extra.

Now, researchers at MIT have discovered that these chemical patterns additionally exist in conventionally manufactured metals. The shocking discovering revealed a brand new bodily phenomenon that explains the persistent patterns.

In a paper printed in Nature Communications at present, the researchers describe how they tracked the patterns and found the physics that explains them. The authors additionally developed a easy mannequin to foretell chemical patterns in metals, they usually present how engineers may use the mannequin to tune the impact of such patterns on metallic properties, to be used in aerospace, semiconductors, nuclear reactors, and extra.

“The conclusion is: You may by no means fully randomize the atoms in a steel. It doesn’t matter the way you course of it,” says Rodrigo Freitas, the TDK Assistant Professor within the Division of Supplies Science and Engineering. “That is the primary paper displaying these non-equilibrium states which might be retained within the steel. Proper now, this chemical order isn’t one thing we’re controlling for or listening to after we manufacture metals.”

For Freitas, an early-career researcher, the findings provide vindication for exploring a crowded subject that he says few believed would result in distinctive or broadly impactful outcomes. He credit the U.S. Air Pressure Workplace of Scientific Analysis, which supported the work by way of their Younger Investigator Program. He additionally credit the collaborative effort that enabled the paper, which options three MIT PhD college students as co-first authors: Mahmudul Islam, Yifan Cao, and Killian Sheriff.

“There was the query of whether or not I ought to even be tackling this particular downside as a result of individuals have been engaged on it for a very long time,” Freitas says. “However the extra I discovered about it, the extra I noticed researchers had been fascinated with this in idealized laboratory situations. We needed to carry out simulations that had been as real looking as attainable to breed these manufacturing processes with excessive constancy. My favourite a part of this venture is how non-intuitive the findings are. The truth that you can not fully combine one thing collectively, individuals didn’t see that coming.”

From surprises to theories

Freitas’ analysis crew started with a sensible query: How briskly do chemical components combine throughout steel processing? Standard knowledge held that there’s some extent the place the chemical composition of metals turns into fully uniform from mixing throughout manufacturing. By discovering that time, the researchers thought they may develop a easy technique to design alloys with totally different ranges of atomic order, often known as short-range order.

The researchers used machine-learning strategies to trace tens of millions of atoms as they moved and rearranged themselves beneath circumstances that mimicked steel processing.

“The very first thing we did was to deform a chunk of steel,” Freitas explains. “That’s a standard step throughout manufacturing: You roll the steel and deform it and warmth it up once more and deform it just a little extra, so it develops the construction you need. We did that and we tracked chemical order. The thought was as you deform the fabric, its chemical bonds are damaged and that randomizes the system. These violent manufacturing processes basically shuffle the atoms.”

The researchers hit a snag through the mixing course of: The alloys by no means reached a completely random state. That was a shock, as a result of no identified bodily mechanism may clarify the outcome.

“It pointed to a brand new piece of physics in metals,” the researchers write within the paper. “It was a type of instances the place utilized analysis led to a elementary discovery.”

To uncover the brand new physics, the researchers developed computational instruments, together with high-fidelity machine-learning fashions, to seize atomic interactions, together with new statistical strategies that quantify how chemical order adjustments over time. They then utilized these instruments in large-scale molecular dynamics simulations to trace how atoms rearrange throughout processing.

The researchers discovered some normal chemical preparations of their processed metals, however at increased temperatures than would usually be anticipated. Much more surprisingly, they discovered fully new chemical patterns by no means seen exterior of producing processes. This was the primary time such patterns had been noticed. The researchers referred to the patterns as “far-from-equilibrium states.”

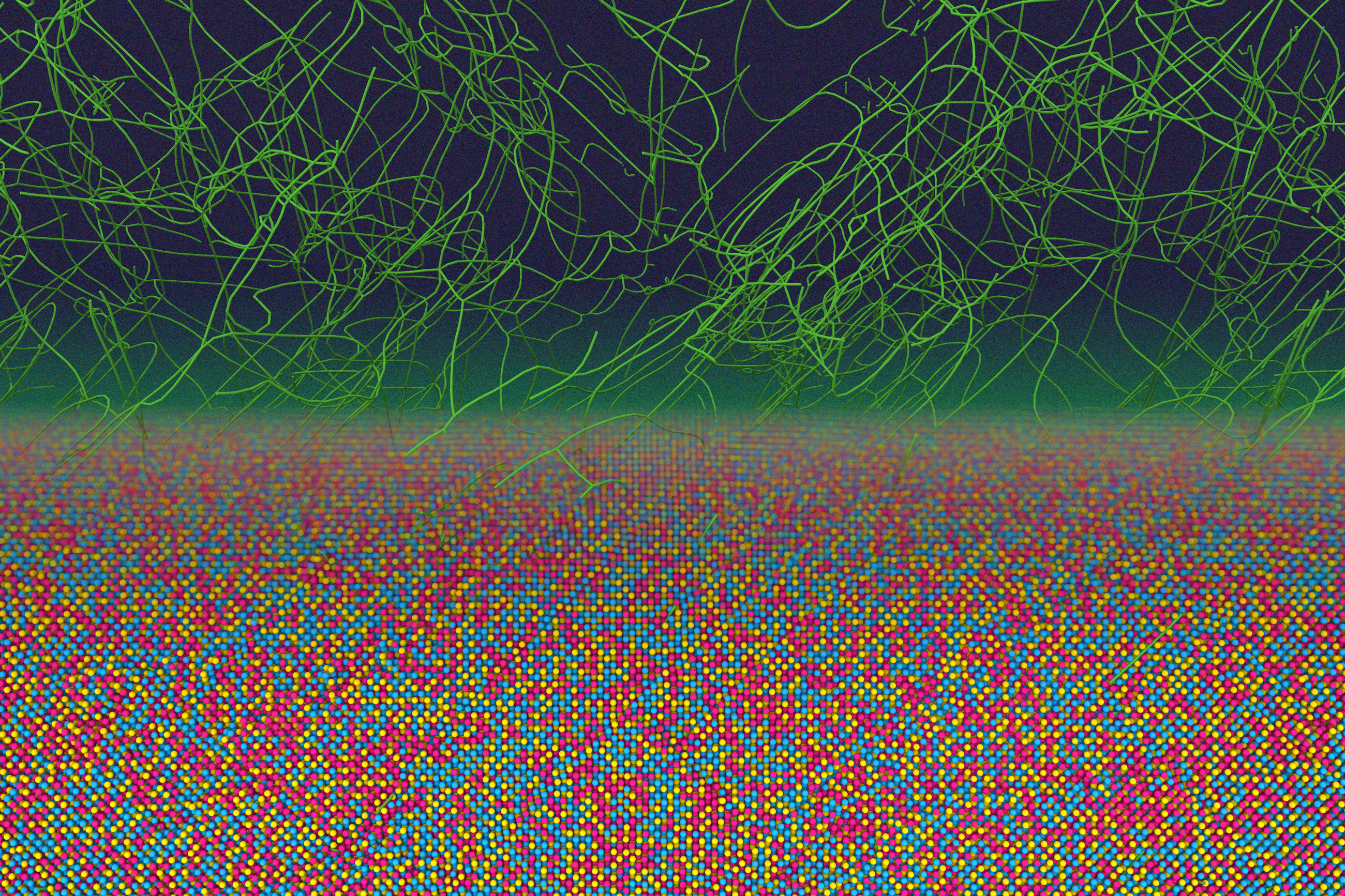

The researchers additionally constructed a easy mannequin that reproduced key options of the simulations. The mannequin explains how the chemical patterns come up from defects referred to as dislocations, that are like three-dimensional scribbles inside a steel. Because the steel is deformed, these scribbles warp, shuffling close by atoms alongside the way in which. Beforehand, researchers believed that shuffling fully erased order within the metals, however they discovered that dislocations favor some atomic swaps over others, ensuing not in randomness however in delicate patterns that designate their findings.

“These defects have chemical preferences that information how they transfer,” Freitas says. “They search for low power pathways, so given a alternative between breaking chemical bonds, they have a tendency to interrupt the weakest bonds, and it’s not fully random. That is very thrilling as a result of it’s a non-equilibrium state: It’s not one thing you’d see naturally occurring in supplies. It’s the identical approach our our bodies dwell in non-equilibrium. The temperature exterior is at all times hotter or colder than our our bodies, and we’re sustaining that regular state equilibrium to remain alive. That’s why these states exist in steel: the stability between an inner push towards dysfunction plus this ordering tendency of breaking sure bonds which might be at all times weaker than others.”

Making use of a brand new principle

The researchers are actually exploring how these chemical patterns develop throughout a variety of producing circumstances. The result’s a map that hyperlinks numerous steel processing steps to totally different chemical patterns in steel.

Thus far, this chemical order and the properties they tune have been largely thought of an instructional topic. With this map, the researchers hope engineers can start considering of those patterns as levers in design that may be pulled throughout manufacturing to get new properties.

“Researchers have been wanting on the methods these atomic preparations change metallic properties — a giant one is catalysis,” Freitas says of the method that drives chemical reactions. “Electrochemistry occurs on the floor of the steel, and it’s very delicate to native atomic preparations. And there have been different properties that you just would not suppose can be influenced by these elements. Radiation harm is one other massive one. That impacts these supplies’ efficiency in nuclear reactors.”

Researchers have already instructed Freitas the paper may assist clarify different shock findings about metallic properties, and he’s excited for the sphere to maneuver from elementary analysis into chemical order to extra utilized work.

“You may consider areas the place you want very optimized alloys like aerospace,” Freitas says. “They care about very particular compositions. Superior manufacturing now makes it attainable to mix metals that usually wouldn’t combine by way of deformation. Understanding how atoms truly shuffle and blend in these processes is essential, as a result of it’s the important thing to gaining power whereas nonetheless holding the low density. So, this may very well be an enormous deal for them.”

This work was supported, partially, by the U.S. Air Pressure Workplace of Scientific Analysis, MathWorks, and the MIT-Portugal Program.