Generative synthetic intelligence fashions have left such an indelible affect on digital content material creation that it’s getting tougher to recall what the web was like earlier than it. You may name on these AI instruments for intelligent initiatives similar to movies and photographs — however their aptitude for the inventive hasn’t fairly crossed over into the bodily world simply but.

So why haven’t we seen generative AI-enabled customized objects, similar to telephone circumstances and pots, in locations like houses, places of work, and shops but? In line with MIT Laptop Science and Synthetic Intelligence Laboratory (CSAIL) researchers, a key concern is the mechanical integrity of the 3D mannequin.

Whereas AI will help generate customized 3D fashions that you would be able to fabricate, these methods don’t typically contemplate the bodily properties of the 3D mannequin. MIT Division of Electrical Engineering and Laptop Science (EECS) PhD pupil and CSAIL engineer Faraz Faruqi has explored this trade-off, creating generative AI-based methods that may make aesthetic modifications to designs whereas preserving performance, and one other that modifies buildings with the specified tactile properties customers wish to really feel.

Making it actual

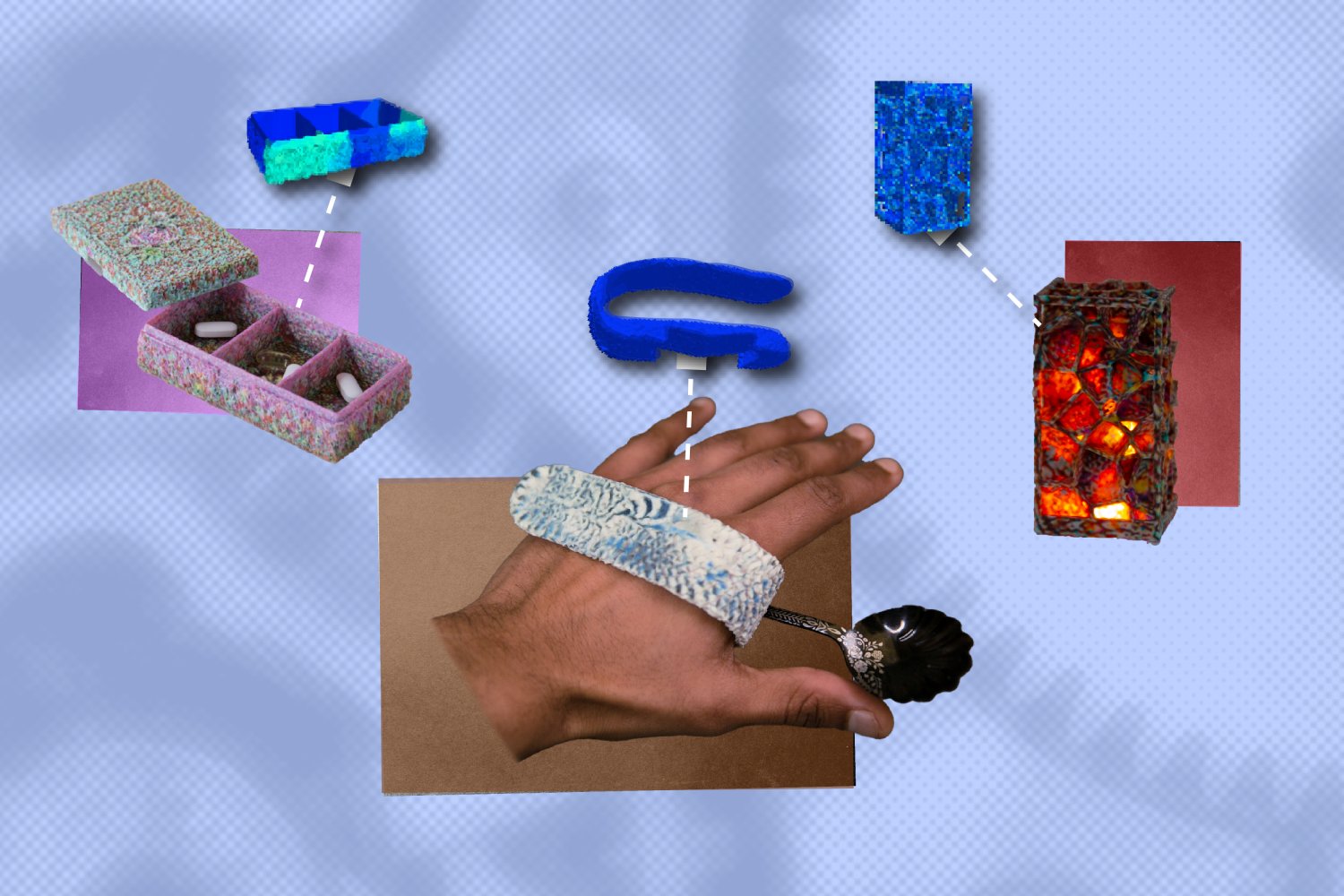

Along with researchers at Google, Stability AI, and Northeastern College, Faruqi has now discovered a technique to make real-world objects with AI, creating objects which can be each sturdy and exhibit the consumer’s meant look and texture. With the AI-powered “MechStyle” system, customers merely add a 3D mannequin or choose a preset asset of issues like vases and hooks, and immediate the instrument utilizing photos or textual content to create a customized model. A generative AI mannequin then modifies the 3D geometry, whereas MechStyle simulates how these modifications will affect explicit elements, making certain susceptible areas stay structurally sound. Whenever you’re pleased with this AI-enhanced blueprint, you may 3D print it and use it in the actual world.

You possibly can choose a mannequin of, say, a wall hook, and the fabric you’ll be printing it with (for instance, plastics like polylactic acid). Then, you may immediate the system to create a customized model, with instructions like, “generate a cactus-like hook.” The AI mannequin will work in tandem with the simulation module and generate a 3D mannequin resembling a cactus whereas additionally having the structural properties of a hook. This inexperienced, ridged accent can then be used to hold up mugs, coats, and backpacks. Such creations are doable thanks, partly, to a stylization course of, the place the system modifications a mannequin’s geometry based mostly on its understanding of the textual content immediate, and dealing with the suggestions obtained from the simulation module.

In line with CSAIL researchers, 3D stylization used to come back with unintended penalties. Their formative examine revealed that solely about 26 % of 3D fashions remained structurally viable after they had been modified, that means that the AI system didn’t perceive the physics of the fashions it was modifying.

“We wish to use AI to create fashions that you would be able to really fabricate and use in the actual world,” says Faruqi, who’s a lead writer on a paper presenting the undertaking. “So MechStyle really simulates how GenAI-based modifications will affect a construction. Our system means that you can personalize the tactile expertise to your merchandise, incorporating your private type into it whereas making certain the article can maintain on a regular basis use.”

This computational thoroughness may ultimately assist customers personalize their belongings, creating a novel pair of glasses with speckled blue and beige dots resembling fish scales, for instance. It additionally produced a pillbox with a rocky texture that’s checkered with pink and aqua spots. The system’s potential extends to crafting distinctive house and workplace decor, like a lampshade resembling crimson magma. It may even design assistive know-how match to customers’ specs, similar to finger splints to help with dexterous accidents and utensil grips to help with motor impairments.

Sooner or later, MechStyle may be helpful in creating prototypes for equipment and different handheld merchandise you may promote in a toy store, ironmongery shop, or craft boutique. The purpose, CSAIL researchers say, is for each professional and novice designers to spend extra time brainstorming and testing out totally different 3D designs, as an alternative of assembling and customizing objects by hand.

Staying robust

To make sure MechStyle’s creations may face up to each day use, the researchers augmented their generative AI know-how with a sort of physics simulation known as a finite aspect evaluation (FEA). You may think about a 3D mannequin of an merchandise, similar to a pair of glasses, with a kind of warmth map indicating which areas are structurally viable below a practical quantity of weight, and which of them aren’t. As AI refines this mannequin, the physics simulations spotlight which elements of the mannequin are getting weaker and stop additional modifications.

Faruqi provides that operating these simulations each time a change is made drastically slows down the AI course of, so MechStyle is designed to know when and the place to do extra structural analyses. “MechStyle’s adaptive scheduling technique retains observe of what modifications are taking place in particular factors within the mannequin. When the genAI system makes tweaks that endanger sure areas of the mannequin, our method simulates the physics of the design once more. MechStyle will make subsequent modifications to ensure the mannequin doesn’t break after fabrication.”

Combining the FEA course of with adaptive scheduling allowed MechStyle to generate objects that had been as excessive as 100% structurally viable. Testing out 30 totally different 3D fashions with kinds resembling issues like bricks, stones, and cacti, the staff discovered that essentially the most environment friendly technique to create structurally viable objects was to dynamically determine weak areas and tweak the generative AI course of to mitigate its impact. In these eventualities, the researchers discovered that they might both cease stylization utterly when a selected stress threshold was reached, or step by step make smaller refinements to stop at-risk areas from approaching that mark.

The system additionally affords two totally different modes: a freestyle characteristic that permits AI to rapidly visualize totally different kinds in your 3D mannequin, and a MechStyle one which fastidiously analyzes the structural impacts of your tweaks. You may discover totally different concepts, then attempt the MechStyle mode to see how these creative thrives will have an effect on the sturdiness of explicit areas of the mannequin.

CSAIL researchers add that whereas their mannequin can guarantee your mannequin stays structurally sound earlier than being 3D printed, it’s not but capable of enhance 3D fashions that weren’t viable to start with. Should you add such a file to MechStyle, you’ll obtain an error message, however Faruqi and his colleagues intend to enhance the sturdiness of these defective fashions sooner or later.

What’s extra, the staff hopes to make use of generative AI to create 3D fashions for customers, as an alternative of stylizing presets and user-uploaded designs. This might make the system much more user-friendly, in order that those that are much less accustomed to 3D fashions, or can’t discover their design on-line, can merely generate it from scratch. Let’s say you wished to manufacture a novel kind of bowl, and that 3D mannequin wasn’t obtainable in a repository; AI may create it for you as an alternative.

“Whereas style-transfer for 2D photos works extremely properly, not many works have explored how this switch to 3D,” says Google Analysis Scientist Fabian Manhardt, who wasn’t concerned within the paper. “Primarily, 3D is a way more troublesome job, as coaching information is scarce and altering the article’s geometry can hurt its construction, rendering it unusable in the actual world. MechStyle helps resolve this drawback, permitting for 3D stylization with out breaking the article’s structural integrity through simulation. This provides individuals the ability to be inventive and higher categorical themselves by merchandise which can be tailor-made in the direction of them.”

Farqui wrote the paper with senior writer Stefanie Mueller, who’s an MIT affiliate professor and CSAIL principal investigator, and two different CSAIL colleagues: researcher Leandra Tejedor SM ’24, and postdoc Jiaji Li. Their co-authors are Amira Abdel-Rahman PhD ’25, now an assistant professor at Cornell College, and Martin Nisser SM ’19, PhD ’24; Google researcher Vrushank Phadnis; Stability AI Vice President of Analysis Varun Jampani; MIT Professor and Middle for Bits and Atoms Director Neil Gershenfeld; and Northeastern College Assistant Professor Megan Hofmann.

Their work was supported by the MIT-Google Program for Computing Innovation. It was introduced on the Affiliation for Computing Equipment’s Symposium on Computational Fabrication in November.