A global workforce of scientists has found a record-breaking methodology of eradicating a category of dangerous ‘eternally chemical compounds’ from contaminated water.

Their filtration approach can mop up giant quantities of per- and polyfluoroalkyl substances, aka PFAS, about “100 instances sooner than business carbon filters,” claims lead writer and engineer Youngkun Chung from Rice College within the US.

PFAS are artificial substances used to guard surfaces from water, fireplace, and grease. Manufactured for the reason that Forties, they’re utilized in raincoats, upholstery, non-stick pans, meals packaging, firefighting foams, and way more.

Associated: ‘Eternally Chemical substances’ in US Ingesting Water Linked to Most cancers, Scientists Discover

frameborder=”0″ enable=”accelerometer; autoplay; clipboard-write; encrypted-media; gyroscope; picture-in-picture; web-share” referrerpolicy=”strict-origin-when-cross-origin” allowfullscreen>

They actually proved sturdy: the carbon-fluorine chain on the core of those molecules is so robust, PFAS are anticipated to take 1000’s of years to interrupt down.

Now they’re in our water, soil, air, and our bodies. That is an issue, as a result of we all know at the very least two of those ‘eternally chemical compounds’ – PFOA and PFOS – are linked to most cancers, heart problems, fertility points, and beginning defects.

Greater than 12,000 different variants stay in the marketplace right this moment, with largely unknown well being results.

Governments and trade are making efforts to wash up the mess, however present strategies are gradual and might create secondary waste.

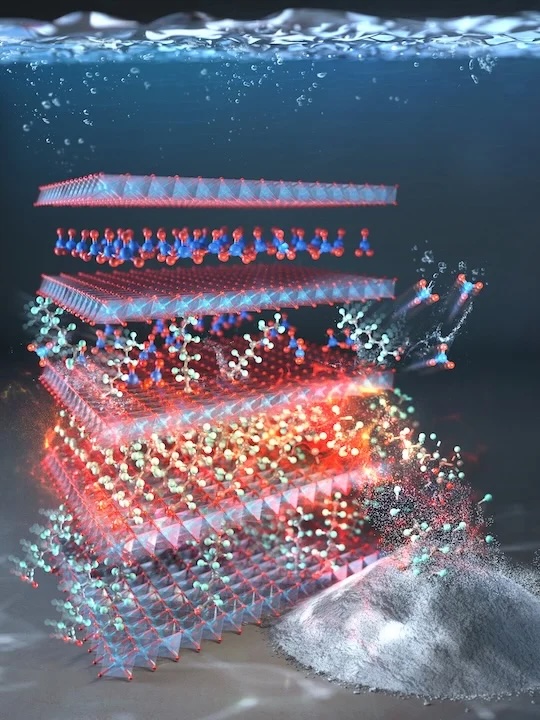

This new filtration methodology makes use of a layered double hydroxide (LDH) materials that mixes copper and aluminum with nitrate.

“This LDH compound captured PFAS greater than 1,000 instances higher than different supplies,” Chung says. “It additionally labored extremely quick, eradicating giant quantities of PFAS inside minutes, about 100 instances sooner than business carbon filters.”

The fabric’s distinctive construction emerges from layers of copper and aluminum with a slight imbalance of their cost, sucking in PFOA molecules, which bind tightly with the filter.

As soon as the adsorption materials was saturated with PFOA, the workforce heated the fabric and added calcium carbonate, which allowed them to ‘clear’ the LDH for reuse and strip the PFOA of its fluorine spine, successfully destroying it.

The remaining fluorine-calcium materials may be disposed into landfill safely, Rice engineer Michael Wong instructed The Guardian.

“We’re excited by the potential of this one-of-a-kind LDH-based expertise to remodel how PFAS-contaminated water sources are handled within the close to future,” Wong says.

Although it is early days for the expertise, it has already proven exceptional promise in lab research, particularly for PFOA. The filter proved efficient in checks with PFAS-contaminated water from rivers, faucets, and wastewater remedy crops, and researchers hope sooner or later it may be simply included into ingesting water and wastewater remedy services.

The analysis is printed in Superior Supplies.